Ceratizit - полный каталог 2016. Дополнение 1 EN

для размещения заказа - info@ceratizit.su

Technical information

F60

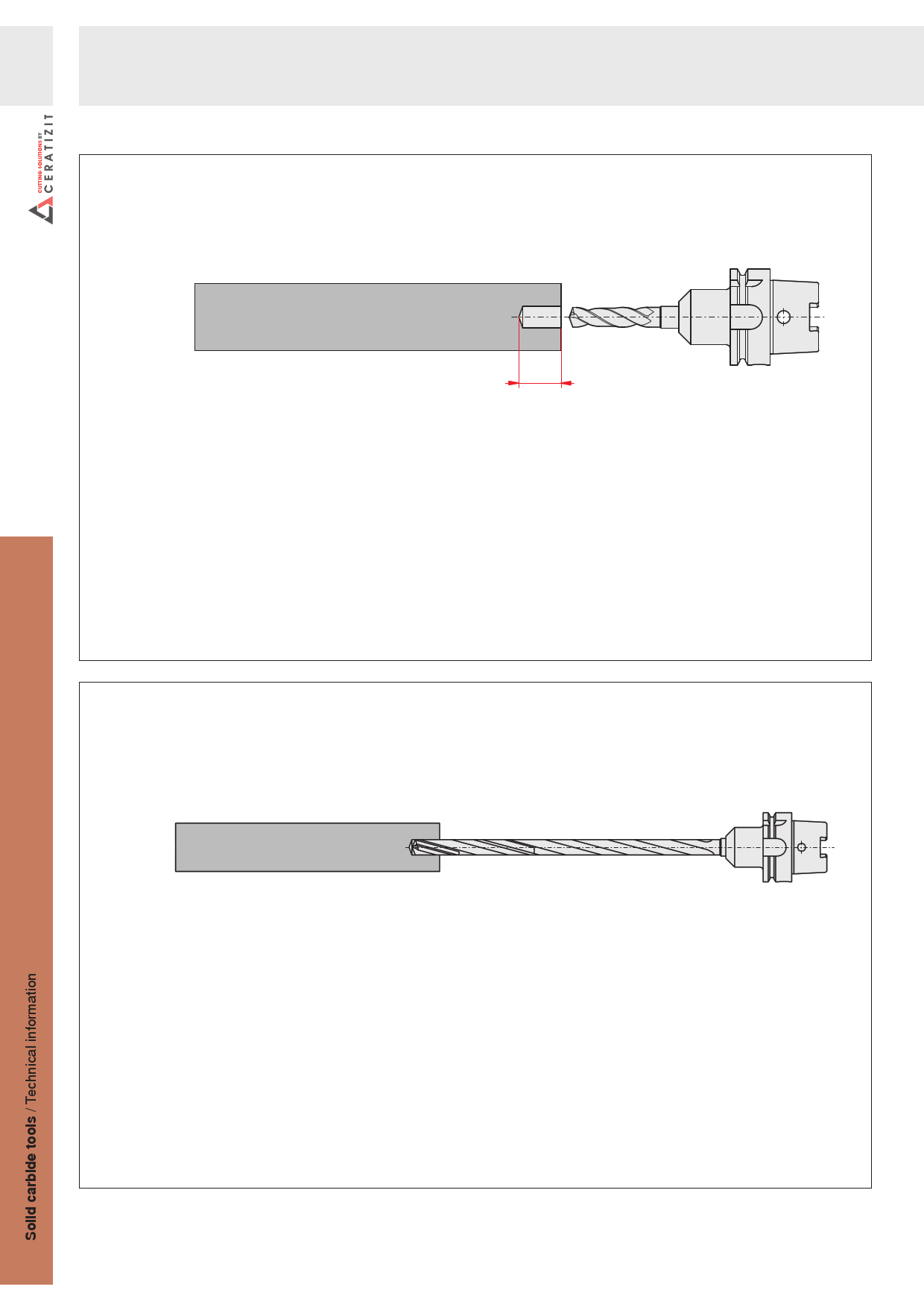

Application of deep hole twist drills 16x and greater

Drill the pilot hole

3xD

For the pilot hole, we recommend our W1106 (for UN) or W1206 (for AL).

The pilot drill should have a 0.02 mm larger diameter (tolerance p6) than the deep hole drill.

Please ensure that the pilot hole is precise and has a minimum depth of 3xD.

For difficult drilling conditions at drilling depths of 40xD and greater we additionally recommend using our W1121 drill

(for UN) as co-pilot drill.

The co-pilot drill should have a larger diameter (tolerance j6) than the deep hole drill.

Please ensure that the pilot hole is precise and has a minimum depth of 20xD.

Please observe the instructions on deep hole drilling up to 40xD.

Enter the pilot hole with the deep hole drill

Deep hole drilling up to 40xD

Use a low rpm (n=300 rev/min) as well as a low feed rate (vf=1000 mm/min) when entering the pilot hole. 1-2 mm before

reaching the bottom of the pilot hole, stop the feed and increase the spindle speed to the recommended value.

Deep hole drilling, 40xD and greater

To enter the pilot hole rotate the drill in a left-hand direction at very low rpm (n=100 rev/min) and a low feed rate (vf=1000

mm/min). 1-2 mm before reaching the bottom of the pilot hole, stop the feed and rotation. With right-hand rotation (i.e.

the normal cutting direction) increase the spindle speed to the recommended value.

info@ceratizit.su

www.ceratizit.su