CERATIZIT - инструмент для обработки камня 2016 EN

для размещения заказа - info@ceratizit.su

INTRODUCTION

CARBIDE – PRODUCTION

7

Carbide production

Carbide production at CERATIZIT started in 1929. Last but

not least, thanks to long-standing experience CERATIZIT

handles the entire process chain, from the raw material to the

dispatching of the finished products to customers. The produc-

tion process of powder-metallurgical products basically inclu-

des the four steps of powder preparation, forming, sintering

and finishing.

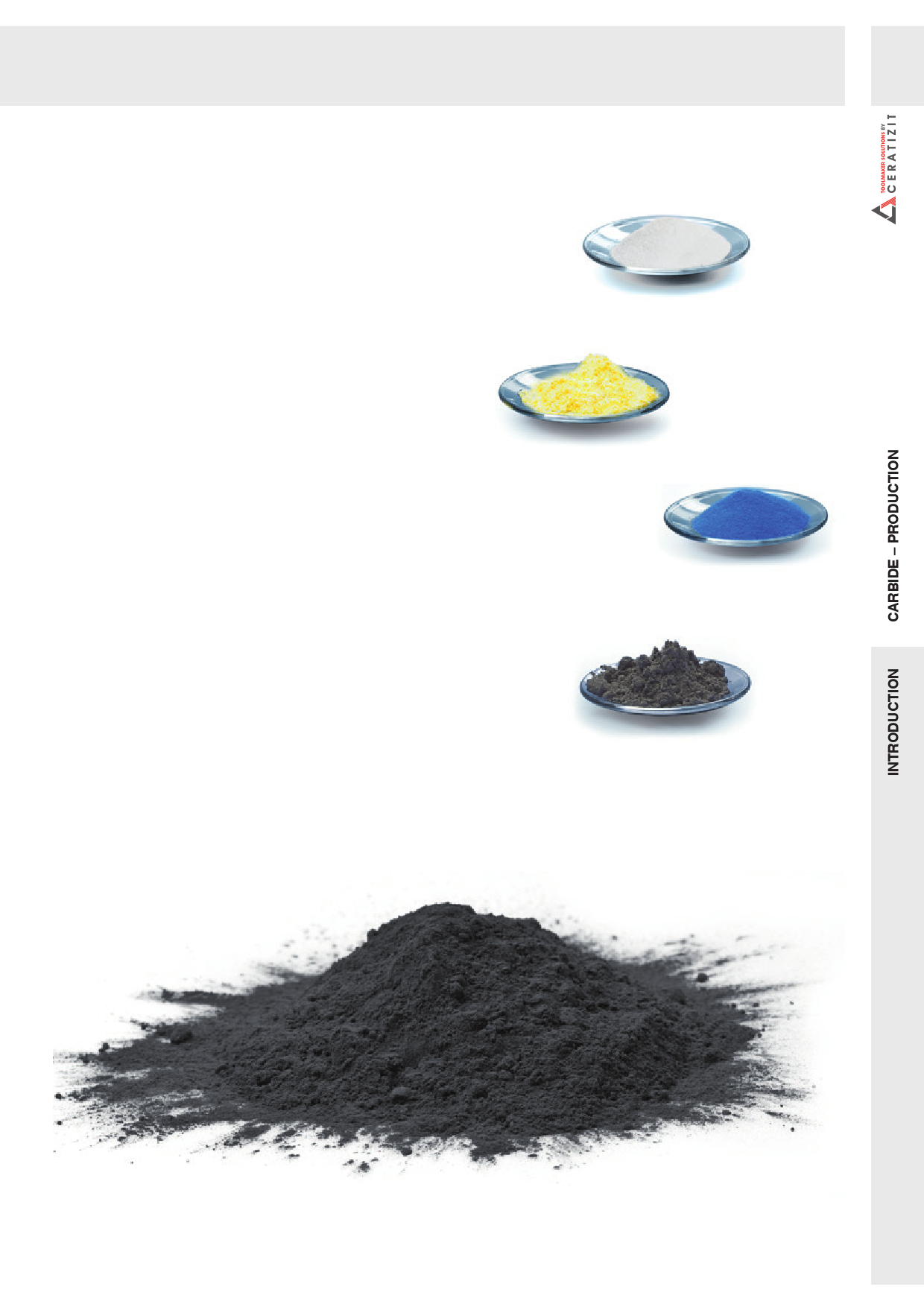

Tungsten carbide production

The APT (ammonium para-tungstate) is calcined into tungs-

ten oxide under high temperature. Subsequently the oxide

is reduced to tungsten metal in a hydrogen atmosphere.

The metal powder is then mixed with carbon and carburised

under inert atmosphere at high temperatures. The production

parameters are decisive for the WC grain size in the sintered

carbide.

Powder preparation

The tungsten carbide is intensely mixed with the binder metal

cobalt, nickel or iron, various grain growth inhibitors and mate-

rials, which promote compaction, by wet grinding so that a

homogeneous suspension is created.

Afterwards, the suspension is dried in a spray tower to pro-

duce a granulate with good flow characteristics. This granulate

represents the basis for all forming processes.

APT (ammonium para-tungstate)

Yellow tungsten oxide

Blue tungsten oxide

Tungsten

Tungsten carbide

info@ceratizit.su

www.ceratizit.su