Ceratizit - полный каталог 2016. Дополнение 2 EN

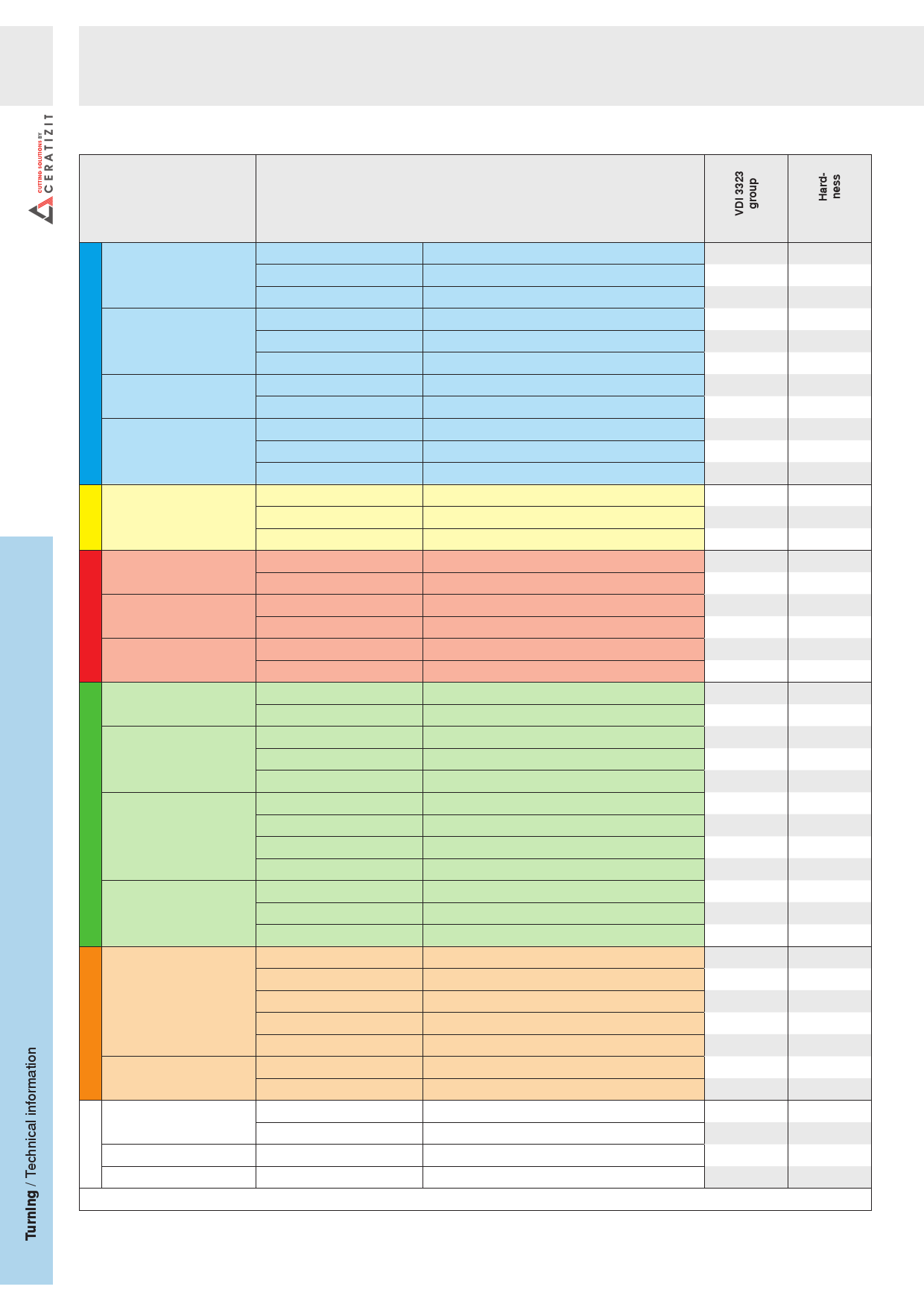

A16 Cutting data

для размещения заказа - info@ceratizit.su

Work piece

material

Non alloyed steel

Low alloyed steel

P

High alloyed steel

Stainless steel

M Stainless steel

Grey cast iron

K Spheroidal cast iron

Malleable cast iron

Aluminium

wrought alloys

Aluminium

cast alloys

N Copper and

copper alloys (bronze,

brass)

annealed

annealed

tempered

annealed

tempered

tempered

annealed

tempered

annealed

tempered

heat-treated

quenched

quenched

hardened

non hardened

hardened

non hardened

hardened

non hardened

Non-metallic materials

Heat-resistant

alloys

S

annealed

hardened

annealed

hardened

cast

Titanium alloys

Tempered steel

H

Chilled castings

hardened and tempered

hardened and tempered

cast

Tempered cast iron

hardened and tempered

* Rm = ultimate tensile strength, measured in MPa

Type of treatment / alloy

0.15 % C

0.15 % - 0.45 % C

0.45 % C

ferritic / martensitic

martensitic

ferritic / martensitic

austenitic

ferritic / austenitic (Duplex)

austenitc, precipitation hardened (PH)

pearlitic / ferritic

pearlitic / martensitic

ferritic

pearlitic

ferritic

pearlitic

< 12 % Si

< 12 % Si

> 12 % Si

machining alloy stock (1% Pb)

brass, red bronze

bronze

lead-free copper and electrolytic copper

thermosetting plastics

fibre-reinforced plastics

hard rubber

Fe-base

Fe-base

Ni or Co-base

Ni or Co-base 30 - 58 HRC

Ni or Co-base 1500 - 2200 N/mm

pure titanium

alpha + beta alloys

info@ceratizit.su

www.ceratizit.su

HB

1 125

2 150 - 250

3 300

6 180

7 / 8 250 - 300

9 350

10 200

11 350

12 200

13 325

13 200

14 180

14 230 - 260

14 330

15 180

16 260

17 160

18 250

19 130

20 230

21 60

22 100

23 75

24 90

25 130

26 (110)

27 90

28 100

28 100

29 –

29 –

30 –

31 200

32 280

33 250

34 (350)

35 (320)

36 Rm 440*

37 Rm 1050*

38 55 HRC

39 60 HRC

40 400

41 55 HRC