Ceratizit - полный каталог 2016. Дополнение 2 EN

для размещения заказа - info@ceratizit.su

F3 Solid carbide tools

Extended product range

High performance x 2

A new generation of end mills

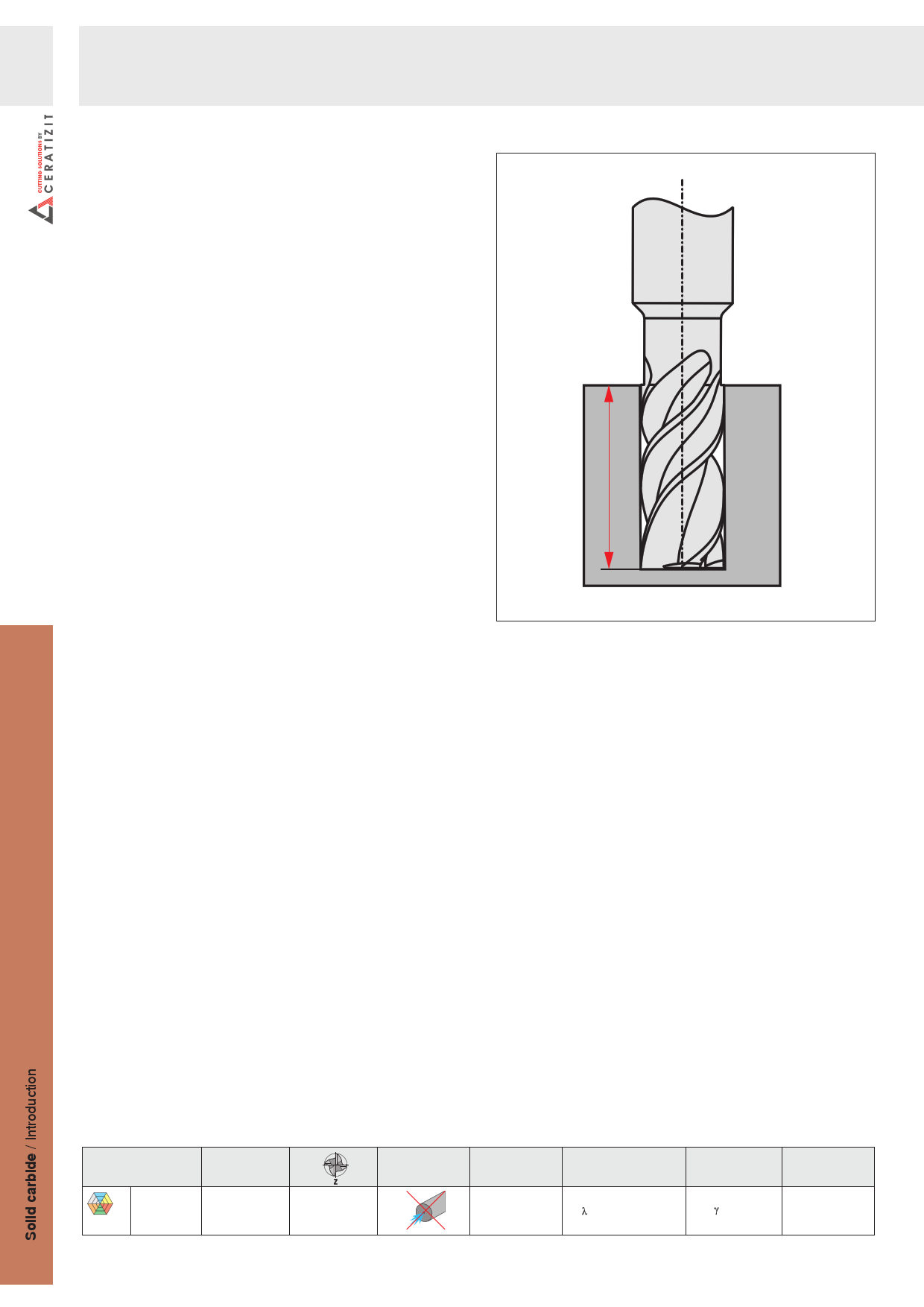

HPC2 W4420 - for universal application:

HPC milling cutters reach higher metal removal rates than con-

ventional end mills. The development of our new HPC2 W4420

end mill has set new standards in the field of HPC machining.

Maximum metal removal rates are achieved thanks to high

feed rates and at large depths of cut. The geometry of the

tool was specially designed for the requirements of this type

of machining. Excellent cutting action together with reduced

vibration during the milling operation ensures good surface

quality.

2xD

Your advantages

Excellent chip evacuation also when full-slot milling

Excellent cutting action due to very positive rake angle

Milling operation with reduced vibration and large depths

of cut for improved process security

Low stress on the spindle – protection of the machine

Long tool life and cutting parameters thanks to grade

SCPP225 and special micro-geometries

Ground neck for large depths of cut

Your benefits

Maximum productivity due to high metal removal rates

Longer tool life with the same metal removal rates for

reduced tooling costs

Secure production processes through increased process

security

HPC2 W4420 end mills

We offer the new solid carbide cutting tool with 4 cutting edges

in diameters from 3 mm to 20 mm for common steel mate-

rials, stainless steels, cast iron and non-ferrous metals. The

geometries specially created for this milling cutter combine the

advantages of small and large rake angles as well as variable

core diameters for deep chip pockets in one tool.

HPC2-SF

ranges

Through-

coolant

Tolerances

Helix angle

Rake angle

Grade

W4420

UN

3 – 20

4

d1 = f8 / dA = h6

s=

22–42°

17–40°

s = 14°

SCPP225

info@ceratizit.su

www.ceratizit.su