Ceratizit - полный каталог инструмента 2016 EN

для размещения заказа - info@ceratizit.su

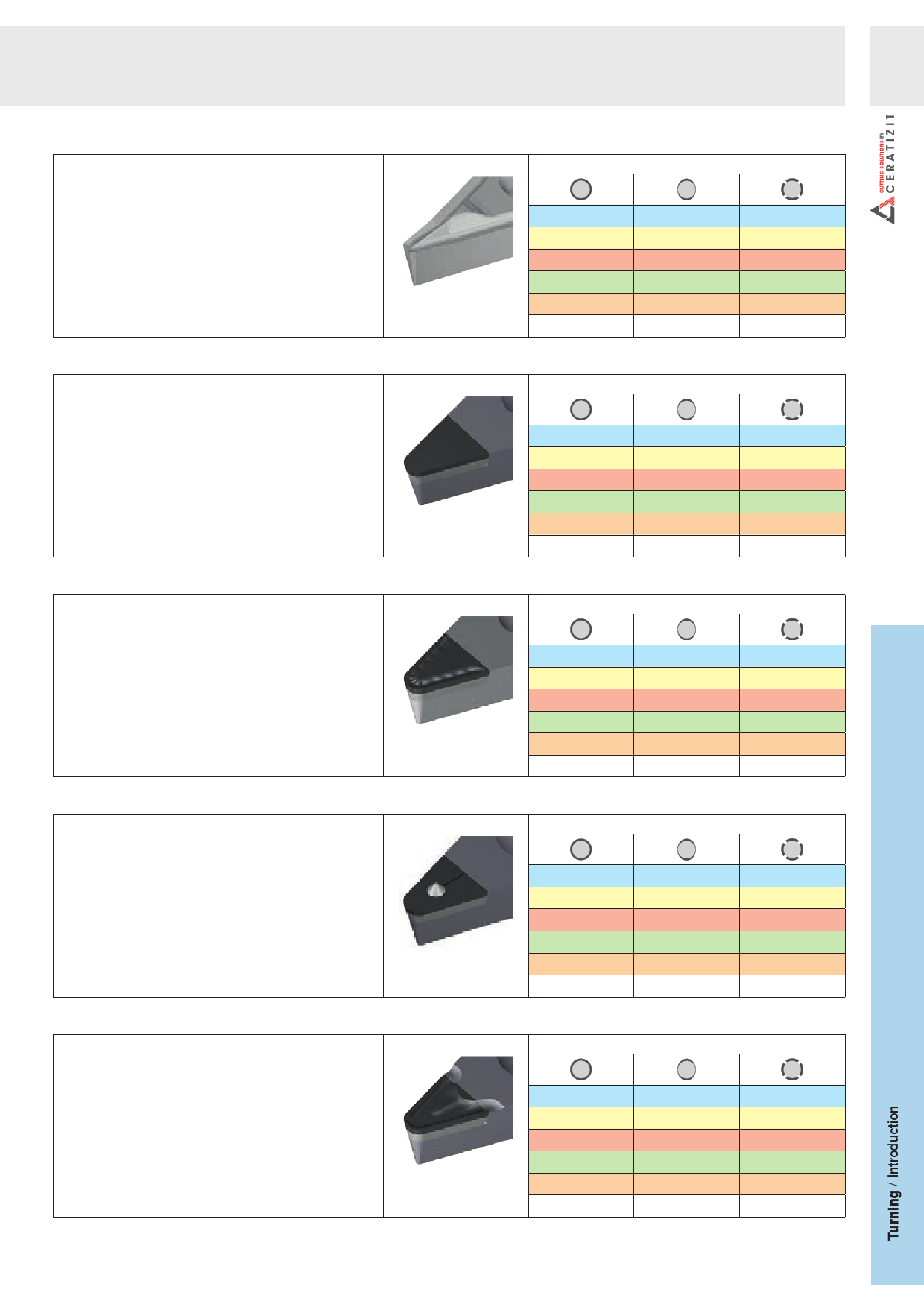

Chip grooves for aluminium wheel machining

A32

-24P

For the machining of wrought aluminium with less than 1 % of

silicon, non-ferrous metals, plastics and refractory metals

Medium and rough machining

Good chip control for a wide range of applications

Machining conditions

H210T, H216T

H210T, H216T

H210T, H216T

-F4

PCD segment without chip groove

Mainly suitable for interrupted cut

Available types of edge preparation: sharp (F), honed (E),

chamfered (T) according to the ISO designation system

Machining conditions

CTD4110

CTD4110

CTD4110

-F41

PCD segment

Chip groove for good chip control and small depths of cut

Available types of edge preparation: sharp (F), honed (E),

chamfered (T) according to the ISO designation system

Machining conditions

CTD4110

CTD4110

CTD4110

-M4

PCD segment with carbide pin to improve chip control with

larger depths of cut

Available types of edge preparation: sharp (F), honed (E),

chamfered (T) according to the ISO designation system

Machining conditions

CTD4110

CTD4110

CTD4110

-M41

PCD segment with proven M41 chip groove

Optimised chip groove for low cutting pressure and ideal chip

form

Available types of edge preparation: sharp (F), honed (E),

chamfered (T) according to the ISO designation system

Machining conditions

CTD4110

CTD4110

CTD4110

info@ceratizit.su

www.ceratizit.su